PP WOVEN DUNNAGE BAG

Brand: MM

Material: Out Bag PP woven, Inner Bag Polymide(PA)

Structure: Out

Bag(PP woven)+Inner Bag (7 layers co-extrusion PA film)+Air valve

G.W: Out Bag

70-218 g/mf, Inner Bag 75-150 g/mf

Thickness: Inner Bag

7.5S-15S/75um-150um

Compressive Strength: 20Kpa-80Kpa/5T-40T

Inner Bag Heat

Seal Strength:≥35N/15MM

Inner Bag Longitudinal Tensile

Strength:≥26Mpa

Inner Bag Lateral Tensile Force:≥26Mpa

Outer Bag

Meridional Tensile Force:z628N/CM

Outer Bag Weft Tensile Strength:z 568N/CM

HIGH EL ASTICITY AND

SOFTNESS

High elasticity, high softness can relieve impact force

9 layers co-extruded nylon membrane with a high-strength PE film bonded toa

PA

(nylon film) through two adhesive layers.

Improve the air tightness of the

air bag, the effect is unparalleled.

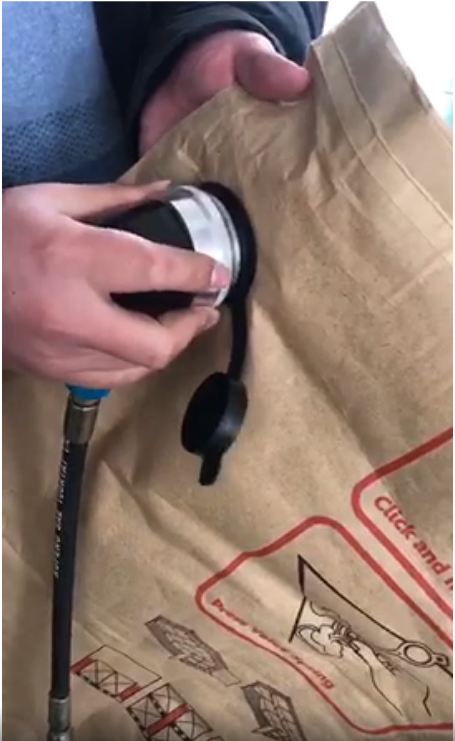

TURBO VALVES

MM inflatable dunnage air bags equipped with a patented valve,

which allows fast

inflation, when connect with the quick inflator, the

time for inflation can be

reduced significantly beside ensuring

consistent pressure.

MORE CONVENIENT TO REUSE

HIGH EL ASTICITY AND

SOFTNESS

Storm-type rotary quick inflation system

Effectively enhances inflation

Make

reuse easier

HOW TO INFLATE A BAG

1.Disclose the cover of the valve

2.Align the muzzle with the valve

mouth

3.Press the airgun vertically until it locked on the valve

4.Push the

switch upward.

5.Hold the airgun start to inflate the bag.

6.Pull out the

airgun when the air pressure in the bag is enough

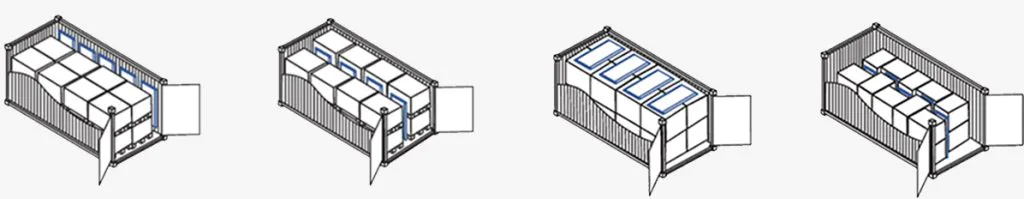

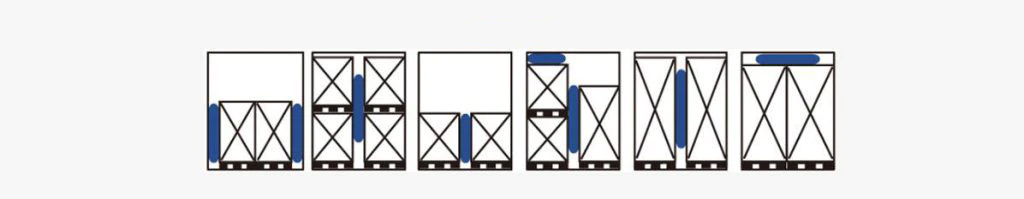

SCENES TO BE USED

Choosing the right type of inflatable bag, designing a reasonable filling scheme, and operating in the right way are the three most critical factors for achieving zero cargo damage.

DEMONSTRATION